Product classification

Mph Combined Cone Crusher

Key words:

Mph Combined Cone Crusher

Classification:

Product Description

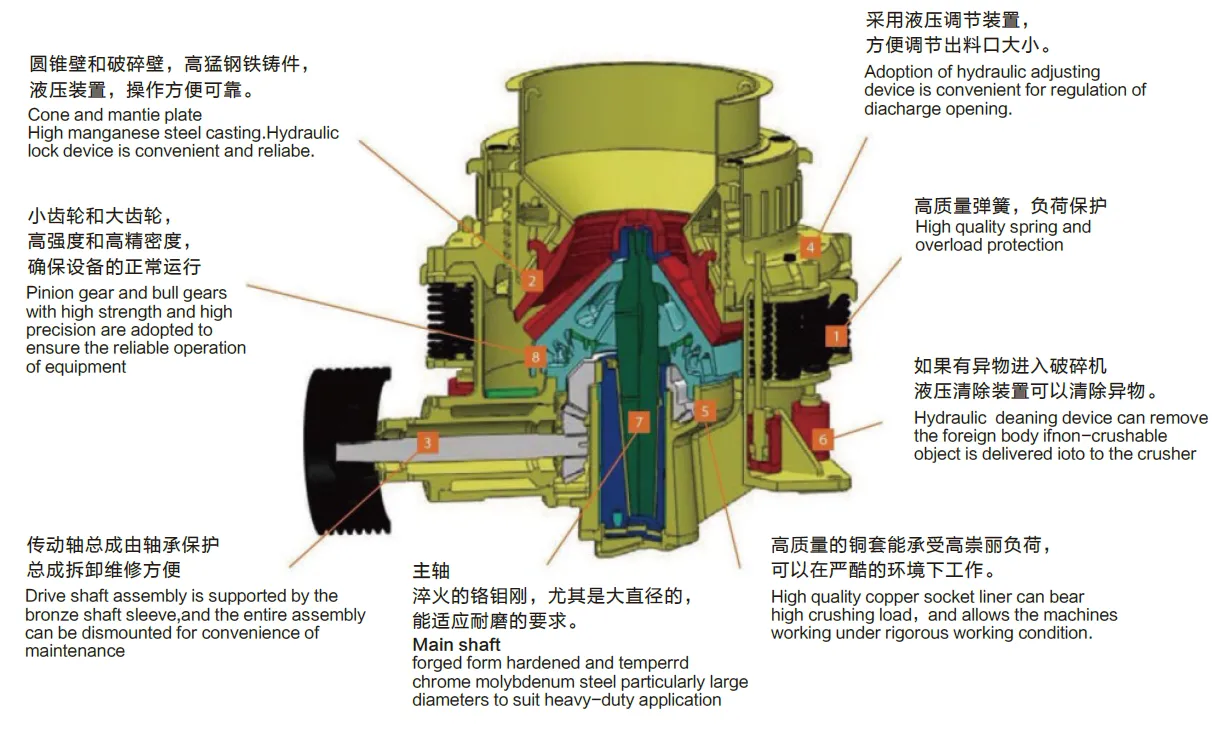

This type of cone crusher is our advantage in the combination of domestic and foreign similar products on the basis of the national patent,launched with the new product. The machine body for cast steel structure,high stress points in overloaded parts set with reinforced. The drive shaft with taper roller bearings, at both ends by driving by overloading bevel gear completed, housings skeleton type sealing ring to prevent oil leakage. Hydraulic structure readjustment, adjust the size of the discharging port.

| 三、TECHNICAL DATA | |||||||||||||||||

| Chamber | Cone Diameter | Max feedsize | Discharge opening | Weight | Motor power | ||||||||||||

| The capacity(tph) of diferent discharge size(mm) | |||||||||||||||||

| (inch) | (mm) | (mm) | (mm) | (t) | (kW) | 6 | 10 | 13 | 16 | 19 | 22 | 25 | 38 | 51 | 64 | ||

| MPH1000 | C | 40" | 1016 | 160 | 13 | 10.8 | 90-110 | 70 | 90 | 125 | 135 | 160 | 215 | ||||

| M | 40" | 1016 | 115 | 10 | 10.8 | 90-110 | 55 | 65 | 70 | 90 | 120 | 135 | |||||

| F | 40" | 1016 | 80 | 8 | 10.8 | 90-110 | 47 | 50 | 60 | 67 | 90 | ||||||

| MPH1200 | C | 45" | 1143 | 180 | 13 | 16 | 110-132 | 105 | 120 | 135 | 160 | 180 | 220 | ||||

| M | 45" | 1143 | 130 | 10 | 16 | 110-132 | 72 | 92 | 105 | 135 | 150 | 170 | |||||

| F | 45" | 1143 | 90 | 10 | 16 | 110-132 | 70 | 90 | 100 | 125 | |||||||

| MPH1300 | C | 51" | 1296 | 200 | 16 | 23 | 132-160 | 135 | 160 | 180 | 200 | 290 | 350 | ||||

| M | 51" | 1296 | 150 | 13 | 23 | 132-160 | 105 | 125 | 135 | 160 | 180 | ||||||

| F | 51" | 1296 | 102 | 10 | 23 | 132-160 | 80 | 105 | 135 | 140 | |||||||

| MPH1400 | C | 54" | 1372 | 215 | 19 | 27 | 185-220 | 180 | 220 | 270 | 350 | 440 | |||||

| M | 54" | 1372 | 160 | 16 | 27 | 185-220 | 160 | 180 | 200 | 230 | |||||||

| F | 54" | 1372 | 115 | 13 | 27 | 185-220 | 150 | 195 | 220 | 240 | |||||||

| MPH1650 | C | 60" | 1524 | 235 | 22 | 37.8 | 220-250 | 230 | 265 | 330 | 450 | 520 | 570 | ||||

| M | 60" | 1524 | 175 | 19 | 37.8 | 220-250 | 215 | 240 | 270 | 330 | |||||||

| F | 60" | 1524 | 130 | 13 | 37.8 | 220-250 | 180 | 210 | 240 | 265 | 285 | ||||||

| MPH1950 | C | 68" | 1720 | 350 | 22 | 44.3 | 300 | 330 | 390 | 525 | 655 | 725 | |||||

| M | 68" | 1720 | 203 | 16 | 44.3 | 300 | 230 | 270 | 300 | 330 | |||||||

| F | 68" | 1720 | 140 | 13 | 44.3 | 300 | 185 | 225 | 265 | 340 | |||||||

| PS:C=Coarse M=edium F=Fine | |||||||||||||||||

Product inquiry

Note: Please leave your email and our professionals will contact you as soon as possible!