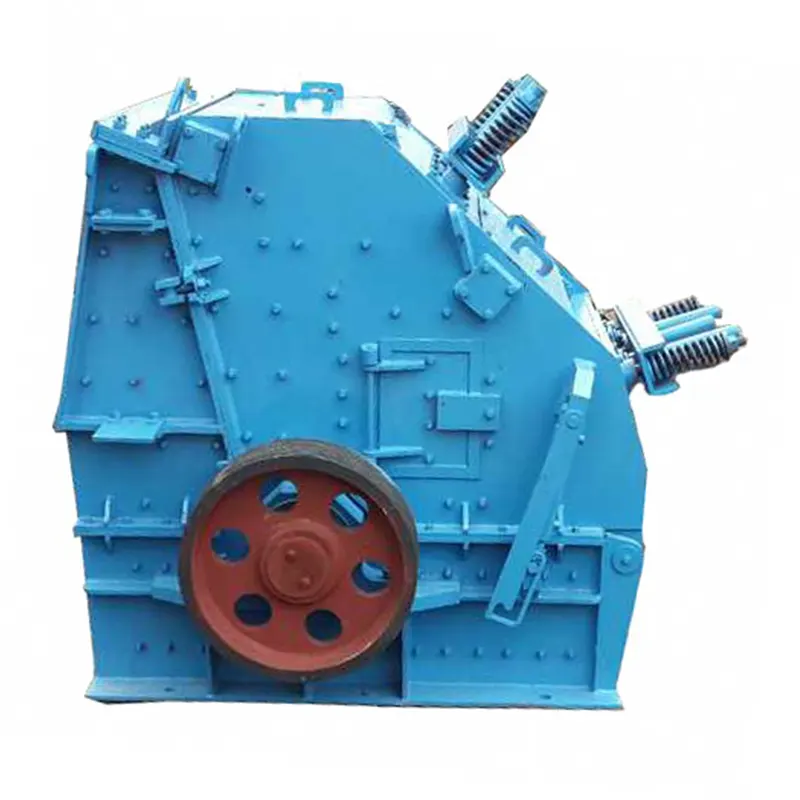

Product classification

S Cone Crusher

Key words:

S Cone Crusher

Classification:

Product Description

S series cone crusher is a high-performance cone crusher with spring insurance, hydraulic adjustment, wedge locking and hydraulic cavity clearance. It is new type of cone crusher with optimized cavity shape and proper stroke, which is developed on the basis of introducing foreign technology and customer needs. It is widely used in for crushing rocks for building materials and for sand making, especially suitable for crushing hard materials such as basalt. It has high efficiency, low operation cost and good product shape.

二、PRODUCT FEATURES

◆ High performance: the combination of optimized cavity shape and proper stroke enables it to have better performance and higher capacity than similar spring insurance cone crushers.

◆ Better product fractions: the principle of inter-particle breakage increases the content of cubic particles and reduces the proportion of elongated particles.

◆ Good stability: when uncrushable materials, such as metal chips, enter the cavity, the hard material protection device will automatically discharge them and then reset. The hard material protection device has a fixed return point, so after the metal chips are discharged, the discharge opening can quickly restore to its original setting.

◆ Easy cavity clearance: if the cone crusher stops under load, the hydraulic system can quickly clear the cavity and the downtime is greatly reduced.

◆ High reliability: big-diameter main shaft, heavy main frame and the automatic control system of the separate oil lubricating system make the equipment solid, durable and reliable during operation.

◆ Separate lubrication: the multi-point controlled separate oil lubricating system can ensure dual protection for the lubrication of the bearings and automatic safety protection of the whole machine.

| 三、TECHNICAL DATA | ||||||

| Model | Cone Diameter | Max.Feed Size | Discharge opening | Capacity | Weight |

Motor power |

| mm(feet) | (mm) | (mm) | (t/h) | (t) | (kW) | |

| S75D | 900(3') | 65 | 6-19 | 27-90 | 10.5 | 75 |

| S75B | 900(3') | 155 | 13-38 | 40-120 | 10.5 | 75 |

| S155D | 1295(41/4') | 90 | 13-31 | 100-180 | 22.6 | 155 |

| S155Z | 1295(41/4') | 155 | 16-38 | 120-250 | 22.6 | 155 |

| S155B | 1295(41/4') | 205 | 19-51 | 145-320 | 22.6 | 155 |

| S155T | 1295(41/4') | 238 | 25-51 | 230-350 | 22.6 | 155 |

| S240D | 1676(51/2') | 90 | 16-38 | 160-305 | 43.9 | 220 |

| S240Z | 1676(51/2') | 155 | 22-51 | 220-420 | 43.9 | 220 |

| S240B | 1676(51/2') | 220 | 25-64 | 250-600 | 43.9 | 220 |

| S240T | 1676(51/2') | 260 | 38-64 | 300-700 | 43.9 | 220 |

| S400D | 2134(7') | 115 | 19-38 | 600-1140 | 104 | 400 |

| S400Z | 2134(7') | 230 | 25-51 | 800-1300 | 104 | 400 |

| S400B | 2134(7') | 315 | 31-64 | 960-1600 | 104 | 400 |

| S400T | 2134(7') | 360 | 38-64 | 1150-1850 | 104 | 400 |

Product inquiry

Note: Please leave your email and our professionals will contact you as soon as possible!