Product classification

HPS Series Multi Cylinder Hydraulic Cone Crusher

Key words:

HPS Series Multi Cylinder Hydraulic Cone Crusher

Classification:

Product Description

HPS series multi-cylinder hydraulic cone crusher is a new type of cone crusher developed after optimal design on the basis of introducing and absorbing advanced hydraulic cone crusher technology from Europe and the United States. It is characterized by the perfect combination of large crushing force, large eccentricity, high crushing frequency and crushing cavity design, which not only improves production capacity and product quality, but also expands the range of applications. Whether it is medium crushing, fine crushing or ultra-fine crushing operations, the multi-cylinder hydraulic cone crusher can be successfully completed. Through the principle of "intergranular lamination crushing", the particle size is more uniform, which greatly reduces the needle sheet material, thereby increasing the value of the product.

二、PRODUCT FEATURES

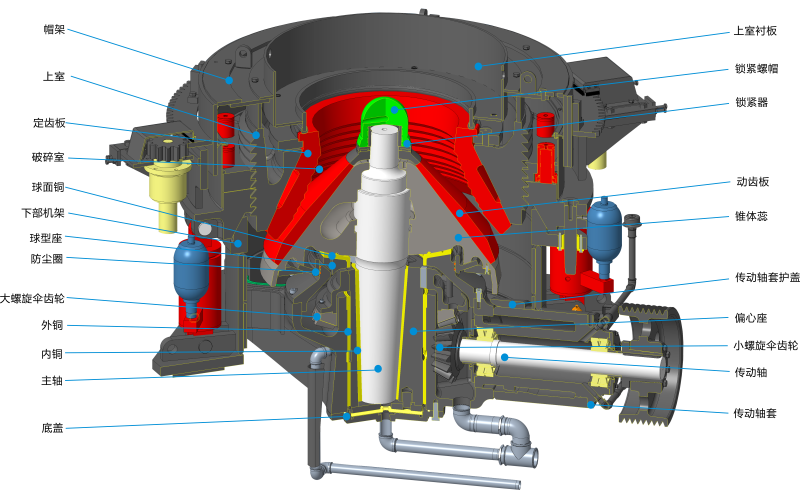

1.Structure upgrade and higher efficiency

At the basis of structure of unique spindle fixation and eccentric sleeve around the main shaft, the transmission rotation parts and the lubrication seal of equipment were further optimized. The carrying capacity of equipment is strong and the installed power reaches the biggest at the same type of industry with small volume, high efficiency and low noise.

2.Full hydraulic control with accurate and reliable

From the insurance clearance to adjust and lock,the equipment was used full hydraulic operation, more stable and reliable, and easy to operate. With rich experience in practice, the hydraulic system has a better structure and more accurate adjustment and control. It can automatically protect the reaction rate faster, but also can realize the full automation operation.

3.Hydraulic lubrication integration and automation of equipment control

Equipped with integration hydraulic lubrication system and centralized automatic intelligent control system,it can save the cost of hydraulic lubrication input ,but also can monitor equipment running state real-time. Further optimization of the control system and more stable and reliable system, guarantee the safe and stable operation of equipment. At the same time, the equipment operation is more worry and effort.

4. Laminated crushing and good product shape

Use the principle of laminated crushing to crush the material and improve the laminating crushing efficiency through the optimization of equipment and the chamber.High crushing efficiency, low wearing parts wear,cube shape of finished product, high content of fine grain size, improve product quality, reduce the production cost of the equipment and the whole system.

5.Multi cavity conversion and one machine with more purposes

Configuration of the multi medium crushing and fine crushing cavities, and only replacing the corresponding liner plated of cavity and a few parts, it can be converted in the cavity type. Combining with the principle of laminated crushing, it’s better to meet the process requirements of medium crushing and fine crushing and realized one machine with more purposes. The mantle and concave were made by the high manganese steel. Due to the crushing cavity changes and the protection of material layer in the process of laminated crushing, the wear is reduced and the general life can be increased from 35% to 82% compared to the old structure of cone crusher."

| 三、TECHNICAL DATA | ||||||||

| Model | Chamber | Max feedsize | Max feedsize | Discharge opening | Capacity | Power | Weight | Dimension |

| (mm) | (r/min) | (mm) | (t/h) | (kW) | (t) | (L1×W1×H1)(mm) | ||

| HPS100 | C | 135 | 800 | 16-32 | 75-130 | 75-112 | 6.8 | 1705×1510×1583 |

| F | 105 | 800 | 13-25 | 55-110 | ||||

| HPS200 | C | 185 | 800 | 22-38 | 180-310 | 110-150 | 12 | 2135×1750×1927 |

| F | 145 | 800 | 19-38 | 145-280 | ||||

| S | 70 | 800 | 13-32 | 90-165 | ||||

| HPS300 | C | 210 | 750 | 22-51 | 210-430 | 180-225 | 18.7 | 2725×2110×2871 |

| F | 185 | 750 | 19-45 | 190-350 | ||||

| S | 90 | 750 | 16-32 | 135-220 | ||||

| HPS400 | C | 290 | 750 | 25-51 | 295-550 | 220-300 | 28.4 | 2775×2370×2295 |

| F | 210 | 750 | 22-45 | 265-440 | ||||

| S | 110 | 750 | 16-32 | 155-256 | ||||

| HPS500 | C | 290 | 750 | 30-59 | 430-790 | 355-400 | 2800×3480×4050 | |

| F | 210 | 750 | 22-49 | 350-580 | ||||

| S | 135 | 750 | 16-38 | 220-410 | ||||

| HPS800 | C | 350 | 750 | 32-60 | 565-1200 | 630 | 3970×3345×4235 | |

| F | 265 | 750 | 25-51 | 475-950 | ||||

| S | 220 | 750 | 19-38 | 310-675 | ||||

| Model | Chamber | Crushing diameter | Feed opening size(mm) | Discharge opening | Capacity | Power | Weight | |

| foot(mm) | Closed edge | Open edge | (mm) | (t/h) | (kW) | (t) | ||

| PYS-DC2120 | SC | 7(2134) | 51 | 105 | 16-25 | 530-718 | 380 | 89.5 |

| PYS-DC2117 | C | 95 | 132 | 13-25 | 408-658 | |||

| PYS-DC2113 | F | 127 | 178 | 10-19 | 318-560 | |||

| PYS-DC2110 | S | 152 | 203 | 5-16 | 172-450 | |||

| PS:SC=Super Coarse C=Coarse F=Fine S=Super Fine | ||||||||

Product inquiry

Note: Please leave your email and our professionals will contact you as soon as possible!