Product classification

Modular Crushing And Screening Equipment

Key words:

Modular Crushing And Screening Equipment

Classification:

Product Description

Modular mobile crushing plants are particularly suitable for multi-point quarries that require regular movement of equipment between different locations, and standard trucks can easily tow them away. With the modular mobile crushing and screening plant equipment, you will not only save time on changing sites, retain the mobility and production capacity of the equipment, but also develop new business opportunities.

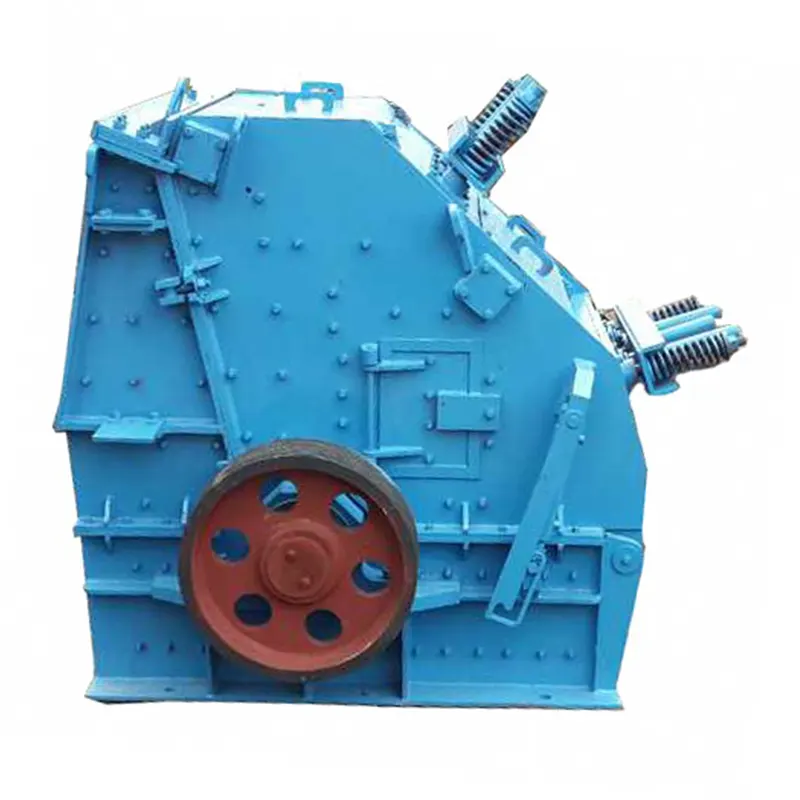

二、JAW CRUSHING PLANT MODULE

MST-C106/C96 modular jaw crushing plant has a maximum feed particle size of 600mm and a processing capacity of 115-580t/h, which is suitable for coarse crushing section. Applicable materials: granite, basalt, pebbles, limestone and other mine rocks below 350MPa.

|

|

|

|

| TECHNICAL DATA | |||

| Project | Name | MST-C110 | MST-C96 |

| Feeding unit | Capacity(t/h) | 150-300 | 150-3000 |

| Max.Feed Size(mm) | 600 | 500 | |

| Feed height(mm) | 4000 | 4000 | |

| Hopper volume(m3) | 5 | 5 | |

| Vibratory Feeder | L×W(mm) | 3500×1050 | 3500×1050 |

| Power(kw) | 3.7×2 | 3.7×2 | |

| Crusher | Jaw crusher | C110 | C96 |

| Feeding Size(mm) | 1060×700 | 930×580 | |

| Max.Feed Size(mm) | 600 | 480 | |

| Weight(T) | 18 | 10.9 | |

| Power(kw) | 110-132 | 90 | |

| Belt conveyor | Stacking height(mm) |

3000 | 3000 |

| L×W(mm) | 11200×B1000 | 11200×B1000 | |

| Power(kw) | 11 | 11 | |

| Iron remover | L×W(mm) | 1670×800 | 1670×800 |

| Power(kw) | 3 | 3 | |

| Crushing unit parameters | Weight(T) | 34 | 23 |

| Capacity(t/h) | 130-300 | 90-220 | |

| Power(kw) | 150.4(153.4) | 108.4(111.4) | |

| Size During Operation(L×W×H)(mm) | 14800×2210×4000 | ||

| Shipping Dimensions(L×W×H)(mm) | 10000×2070×3450 | ||

三、CONE CRUSHING PLANT MODULE

MST-HP300/HP200 modular multi-cylinder cone crushing plant maximum feed size: 185mm, production capacity: 70-210t/h, for medium and fine crushing section. It is suitable for various mining rocks such as iron ore, non-ferrous metal ore, granite, basalt, sandstone, pebbles and other mine rocks with compressive strength below 350MPa. Its crusher can be replaced with single-cylinder hydraulic cone crusher or hydraulic composite cone crusher according to needs.

|

|

|

|

| TECHNICAL DATA | |||

| Project | Name | MST-H300 | MST-H200 |

| Feeding unit | Capacity(t/h) | 150-300 | 120-250 |

| Hopper volume(m3) | 2 | 2 | |

| Belt conveyor | L×W(mm) | 6600×B1000 | 6600×B1000 |

| Feed height(mm) | 2800 | 2800 | |

| Crusher | Cone crusher | HP300 | HP200 |

| Max.Feed Size(mm) | 210 | 185 | |

| Close size(mm) | 16-51 | 13-38 | |

| Weight(T) | 17 | 12 | |

| Power(kw) | 250 | 110-150 | |

| Belt conveyor | Discharge height(mm) | 3000 | 3000 |

| L×W(mm) | 9000×B1000 | 9000×B1000 | |

| Power(kw) | 11 | 11 | |

| Belt conveyor | Discharge height(mm) | 2500 | 2500 |

| L×W(mm) | 6600×B1000 | 6600×B1000 | |

| Power(kw) | 7.5 | 7.5 | |

| Iron remover | L×W(mm) | 4000×1500 | 4000×1500 |

| Power(kw) | 3.7×2 | 3.7×2 | |

| Belt conveyor | L×W(mm) | 2200×B650 | 2200×B650 |

| Power(kw) | 4 | 4 | |

| Belt conveyor | L×W(mm) | 11000×B650 | 11000×B650 |

| Power(kw) | 5.5 | 5.5 | |

| Crushing unit parameters | Weight(T) | 43 | 41 |

| Capacity(t/h) | 120-300 | 100-260 | |

| Power(kw) | 203.9 | 303.9 | |

| Size During Operation(L×W×H)(mm) | 18300×4300×4800 | ||

| Shipping Dimensions(L×W×H)(mm) | 18300×2500×3590 | ||

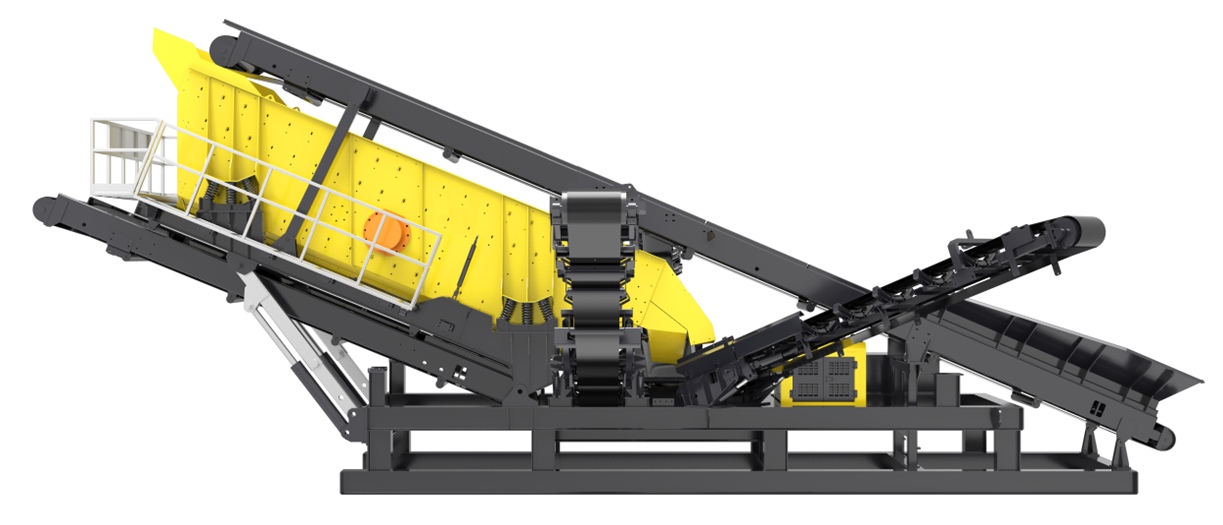

四、SCREENING PLANT MODULE

MST-S1860 module screening plant is used in mining, cement plant, sand and gravel industry, asphalt crushing and screening and other industries. It has excellent screening capacity, easy operation, convenient transition, complete spare parts and screen support.

|

|

|

|

| TECHNICAL DATA | ||

| Project | Name | MST-S1860 |

| Feeding unit | Capacity(t/h) | 150-300 |

| Hopper volume(m3) | 2.5 | |

| Belt conveyor | L×W(mm) | 11500×B1000 |

| Feed height(mm) | 2950 | |

| Vibrating Screen | L×W(mm) | 6000×1800 |

| Power(kw) | 19 | |

| Number of Screen layers | 3 | |

| Belt conveyor A | Stacking height(mm) | 3000 |

| L×W(mm) | 6000×B500 | |

| Power(kw) | 4 | |

| Belt conveyor B | Discharge height(mm) | 3000 |

| L×W(mm) | 6000×B500 | |

| Power(kw) | 4 | |

| Belt conveyor C | Stacking height(mm) | 3000 |

| L×W(mm) | 6000×B500 | |

| Power(kw) | 4 | |

| Belt conveyor D | Discharge height(mm) | 3000 |

| L×W(mm) | 8000×B1000 | |

| Power(kw) | 7.5 | |

| Screening unit parameters | Weight(T) | 27 |

| Processing Capacity(t/h) | 100-300 | |

| Power(kw) | 50 | |

| Size During Operation(L×W×H)(mm) | 15400×13300×5700 | |

| Shipping Dimensions(L×W×H)(mm) | 15400×3600×3700 | |

Product inquiry

Note: Please leave your email and our professionals will contact you as soon as possible!