Product classification

Program-Controlled Automatic Pull-Plate Chamber Filter Press

Key words:

Program-Controlled Automatic Pull-Plate Chamber Filter Press

Classification:

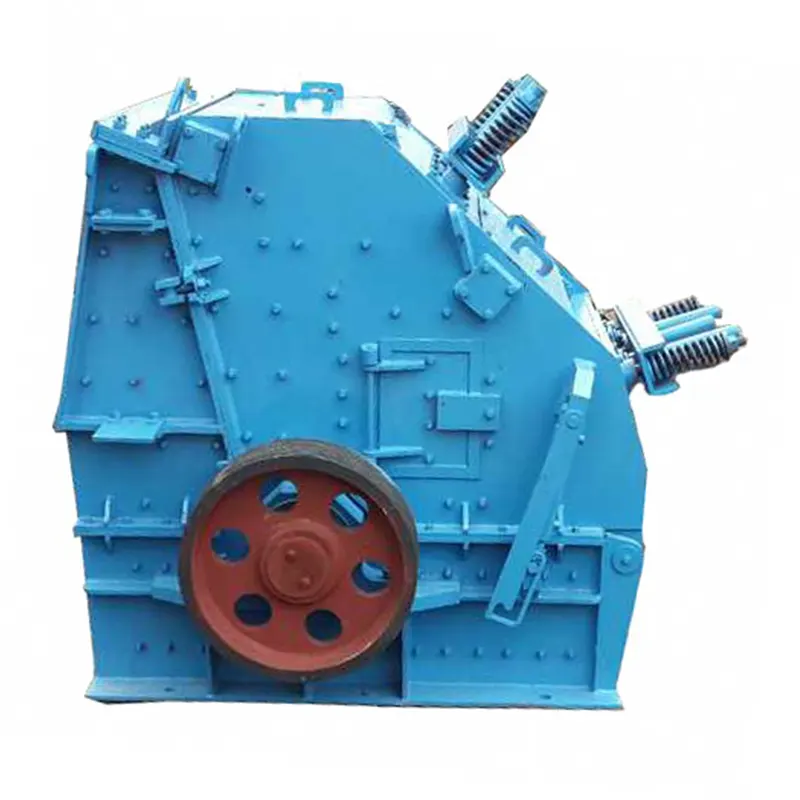

Product Description

The main engine is driven by the oil pump, the oil cylinder starts to work to push the filter plate to the set pressure space, the feeding pump starts the tailings slurry into each filter cavity, under the feed pressure, the slurry is separated into a filter cloth through the filter cloth, and the liquid water is recycled through the drainage device. The filter plate passes the PLC control program, and the trolley automatically opens the pull plate to make the filter cake fall off, and this process reciprocates to achieve solid-liquid separation.

The equipment is simple to operate, durable, safe and reliable, and highly effective. It is suitable for the treatment of tailings slurry in various mining industries such as sand, ceramics, and garbage dumps, and solves the sewage pollution to make it discharge up to standard, and is an efficient tailings dewatering environmental protection equipment.

| 二、TECHNICAL DATA | ||||||||||||

| Model | Filter plate size | Intermediate filter plate | Head and tail plates | Filter pressure | Filter cake weight | Filter press volume | Duty cycle | Cylinder specifications | Number of cylinders | Motor power | Form factor | Weight |

| mm | (slice) | (cover) | (Mpa) | (T) | (m³) | (min) | (mm) | (item) | (KW) | L× W×H(mm) | (T) | |

| ZB250 | 1250×1250 | 91 | 2 | 20 | 6.6 | 4.6 | 35-40 | 250 | 1 | 5.5+0.75 | 10500×2100×1800 | 13.5 |

| ZB500 | 1500×1500 | 122 | 2 | 20 | 14 | 9.6 | 60 | 320 | 2 | 11+1.5 | 13500×2300×1900 | 27 |

| Ф1000(high pressure) | Ф1000×65 | 86 | 2 | 20 | 4 | 2.6 | 40 | 320 | 1 | 4.5+0.75 | 10500×1900×2100 | 11.5 |

| Ф1250(high pressure) | Ф1250×65 | 86 | 2 | 20 | 5.5 | 3.6 | 40 | 320 | 1 | 5.5+0.75 | 10500×2100×2200 | 13 |

| Ф1500(high pressure) | Ф1500×70 | 122 | 2 | 24 | 9.6 | 6.6 | 60-90 | 320 | 2 | 11+0.75 | 13000×2300×2300 | 26 |

Product inquiry

Note: Please leave your email and our professionals will contact you as soon as possible!