Product classification

MR Vertical Shaft Crusher

Key words:

MR Vertical Shaft Crusher

Classification:

Product Description

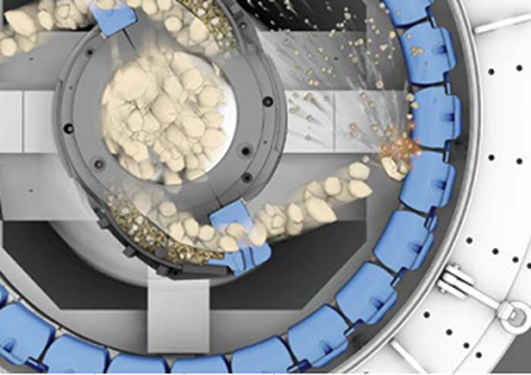

MR Vertical Shaft Impact Crusher (Sand Making Machine) is a vertical shaft type high-performance crusher suitable for all types of mineral crushing and shaping: from soft to hard materials, whether low or very high wear materials. Each particle in the material rotates at high speed in a two-chamber rotor and then flung towards the fixed impact plate. Impact plates can consist of annular liners or sand beds. Clogging is largely avoided by the generous size of the rotor and housing, and all wear protection is a single replaceable consumable.

Compared to the multi-chamber design, the MR vertical shaft impact breaker uses a two-chamber rotor that delivers less air, reducing energy consumption, which can be used to increase productivity and reduce the power of the dust collector. The dual-chamber rotor has an open construction design, allowing the maximum usable size of the outlet (89° per side). This significantly reduces the risk of material clogging. In the MR two-chamber rotor, a layer of material is formed along the crushing chamber that acts as self-wear protection. Compared to conventional rotors, the proportion of wear parts required is reduced to a minimum.

二、PRODUCT FEATURES

| ◆High quality of the final product Produce the high quality cubic shape products,Use centrifugal force to make every feeding grain get the great accelerated speed,The casted materials crush with crushing plate. ◆The quality stable's final product Even if the equipment in operation cause abrasion continually,also doesn't affect the material's crush effect.The system features can avoid the random-effects by material crushing.This is Mr rotor centrifugal crusher's technology characteristics different from other traditional's. ◆Targeted selective crushing For each material particles through targeted shock crushing,The low intensity component materials is easier crushed then high intensity component.in this way,it can remove the easy crushing part's materials on purpose.thus,significantly improve the quality of the final product(wear value,freezing resistance).For the different intensity of components of ores and industrial minerals,Can get the largest number's final product. |

|

| The annular plate structure ◣It is suitable for medium abrasion resistance material production cubic stone and sand making, such as Gravel, limestone, dolomite, diabase, basalt, andesite, brick bat, cement clinker etc. ◣Selective crushing mud gravel and other conglomerate, medium abrasion resistance material of slag and industrial mineral, topsoil, etc. ◣Recycling asphalt , unreinforced concrete block and construction waste, etc. |

|

|

The sand bed structure ◢It is suitable for high abrasion resistance material production cubic stone and sand making, such as Gravel, granite and porphyry, gneiss, miscellaneous sandstone, quartz, etc

|

| 三、TECHNICAL DATA | |||||||

| Model | Speed | Feed Size | Through ability | Power | Weight | Dimension | |

| (m/s) | (mm) | (t/h) | (kw) | (t) | (L×W×H)(mm) | ||

| MR-132 | 60-89 | 30 | 20-35 | 132 | 7.5 | 4200×1988×1870 | |

| MR-160 | 60-89 | 35 | 30-45 | 160 | 7.8 | 4200×1988×1870 | |

| MR-200 | 60-89 | 35 | 40-55 | 200 | 8.3 | 4200×1988×1870 | |

| MR-250 | 60-89 | 40 | 50-80 | 250 | 11.6 | 4200×2400×1980 | |

| MR-315 | 60-89 | 40 | 70-95 | 315 | 12.9 | 5200×2400×2150 | |

| MR-400 | 60-89 | 40 | 100-130 | 200×2 | 15.3 | 5620×3215×2320 | |

| MR-500 | 60-89 | 45 | 120-170 | 250×2 | 16.8 | 5620×3280×2420 | |

| MR-630 | 60-89 | 45 | 150-200 | 315×2 | 18.7 | 5670×3360×2550 | |

| MR-250S | 60-89 | 40 | 120-210 | 250 | 11.5 | 3950×2420*2100 | |

| MR-315S | 60-89 | 40 | 140-270 | 315 | 12.6 | 3950×2550*2140 | |

| MR-400S | 60-89 | 40 | 180-390 | 200×2 | 15.2 | 5200×2520×2220 | |

| MR-500S | 60-89 | 45 | 240-480 | 250×2 | 16.9 | 5600×2630×2610 | |

| MR-630S | 60-89 | 45 | 270-550 | 315×2 | 19.4 | 5670×2750×2680 | |

Product inquiry

Note: Please leave your email and our professionals will contact you as soon as possible!